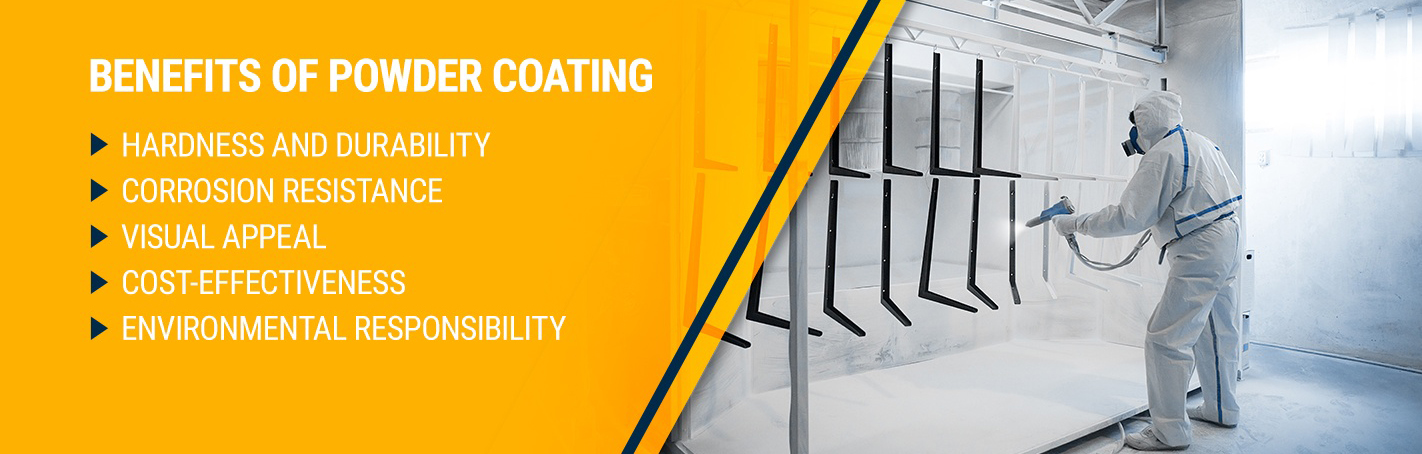

Powder coating is a great way to apply vibrant color that will resist nicks, scratches and other abrasions. This process is a reliable, eco-friendly alternative to wet or liquid coatings. While liquid finishes contain solvents which have pollutants known a volatile organic compounds (VOC’s), powder coatings contain no solvents and release negligible amounts of VOC’s into the atmosphere. This type of coating is harder, tougher, and more durable than the typical liquid coating.

Durability

Powder Coating the furniture makes it highly resistant to wear and tear no matter where it's used. The coating is resistant to chipping, fading, scratching, and rust, it protects the material underneath. This durability makes it well-suited for furniture that come into contact with sunlight and other environmental factors.

Longevity

Powder-coated furniture are extremely easy to maintain over on extended period of time, partly due to their durability. since the material is so durable, you can expect your powder coating to maintain its appearance for a long time. The thermal bonding process ensures the coat will be resistant to many weather and environmental factors.

Eco Friendliness

On top of everything else, powder coating in an environmentally friendly way of coloring the furniture. Even though it is applied by spraying powder, the powder doesn't contain any harsh chemicals designed to make it stick. It address to the metal through the electrical charge on the surface, so no solvents are used.

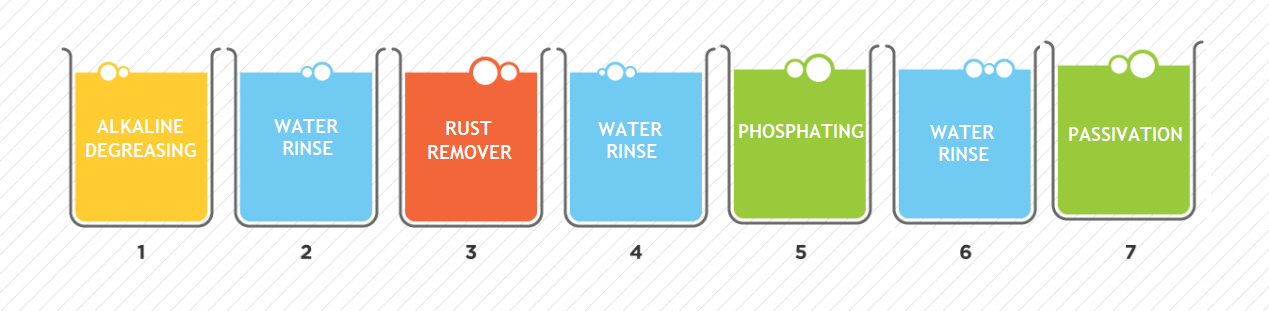

Step1:

We use the 3 in 1 Solution process for Powder Coating. This is a single stage pre-treatment solution for degreasing, de-rusting and phosphating metals such as Iron, Steel, and Aluminium etc.

This solution converts the surface to a complex iron phosphate compound which is totally passive to oxidation. The treated articles can be oiled or painted directly for further rust resistance.

Step2:

Powder coating is a partially cured resin with pigments of color that is ground up into a fine powder which is applied to conductive parts with an electrostatic spray gun.

After application, items are placed in an oven at 400 degrees to complete the cure cycle for a hard, decorative finish.

We remove all oils, lubricants, shop dirt, oxides, fingerprints, and any other contaminants from the surface of the part using our abrasive media blasting.

We apply the powder coating with an electrostatic gun. We then heat the object and the powder melts into a uniform film, when it is cooled it forms a hard coating.

We allow the product to cure on our oven, this process is called crosslinking.

The finished product is placed in our clean room.

There are 3 vital decisions to make in this process:

Powder coatings are available in two basic types, each offering different performance attributes.

| Performance Characteristics | ||

|---|---|---|

| Hardness | Excellent | Good |

| Flexibility | Excellent | Excellent |

| Over-bake Stability | Fair | Excellent |

| Exterior Stability | Poor | Excellent |

| Corrosion Protection | Excellent | Very Good |

| Chemical & Solvent Resistance | Excellent | Good |

| Ease of Application | Very Good | Very Good |

Powder coating can produce a smooth surface or those with many different textures. The type of powder coating finish that’s best for any project varies on the object application and materials chosen

Matt Coating

Glossy Coating

Structure / Textures Coating

Here is a range of colors to choose for the powder coating. Availability is based on volume: